[Jan.2019] Made by Robots – Visiting the NCCR Digital Fabrication Labs 参观ETH机器人制造实验室

机器人制造

参观苏黎世联邦理工学院的Arch_Tec_Lab和机器人制造实验室

Made by Robots

Visiting the Arch_Tec_Lab and the Robotic Fabrication Lab at ETH Zürich

时间:周四 , 2019.01.31 , 18:30

地点:Stefano-Franscini-Platz 1, Building HIB, ETH Hönggerberg

向导:Hannes Mayer

海报:汪弢

摄影:Raphael Kunz

英语报道:江天

中文报道:杨晴川

© Photo credit: Raphael Kunz

© Photo credit: Raphael Kunz

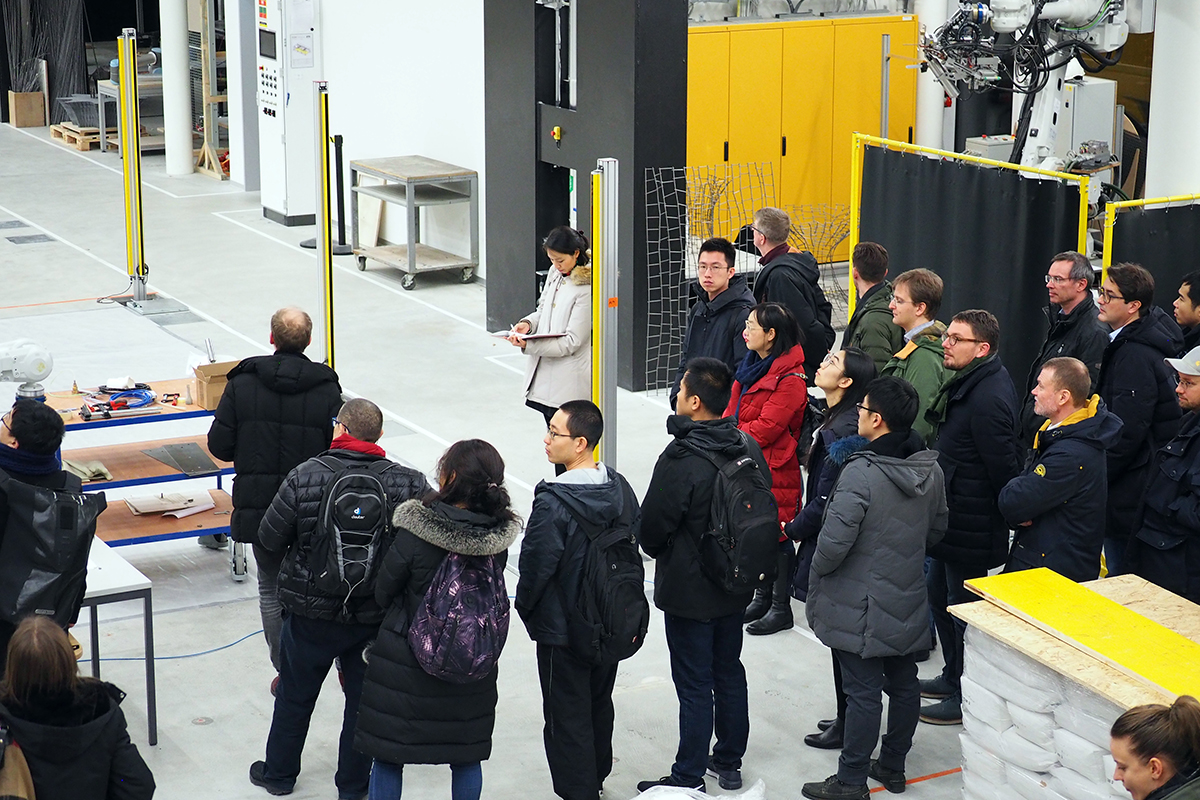

2019年SCAA第一次活动是参观NCCR数字制造实验室。高级研究员Hannes Mayer带着大家参观建筑,目前这里有90名研究人员致力于数字建造建筑。

The first SCAA event in 2019 took an interested audience to the NCCR Digital Fabrication Laboratories. Senior Researcher Hannes Mayer took young and old on a tour through the building where currently 90 researchers work towards digital building architecture.

自2016年以来,Arch_Tech_Lab大楼是苏黎世联邦理工学院建筑技术学院(ITA)的新家。在其二楼,令人印象深刻的木制屋顶结构延伸至整个大厅,覆盖近2’500m2的表面。该建筑由168个桁架,近50,000个板条组成,由一个机器人组装,约有200万个钉子。自由浮动的形式、照明和温暖的材料创造了与技术大厅不同的氛围。

Since 2016 the Arch_Tech_Lab building has been the new home of the Institute of Technology in Architecture (ITA) at the ETH Zurich. On its first floor, an impressive wooden roof structure stretches over the hall, covering a surface of nearly 2’500 sqm. The construction consists of 168 trusses, nearly 50’000 slats, and was assembled by a single robot with around 2 million nails. The free-floating form, the illumination and the warmth of the material create an atmospheric differentiation from the technical hall.

© Photo credit: Raphael Kunz

© Photo credit: Raphael Kunz

Hannes带着观众参观了布置在展厅中的各个原型和模型。在其中一个角落的钢杆模型证明了机器人可以创建复杂的空间结构,因为它们能精确地将元素放置在三维空间中。他们只需要一条无碰撞的路径。

Hannes took the audience around the large hall where prototypes and models were spread around. In one corner, a steel rod model demonstrated that robots could create complex spatial results due to their ability to place elements precisely in 3D space. They just needed a collision-free path to follow.

在另一个角落,一个扭曲的灰色柱子展示了通过编程,以高速(每分钟2厘米)建造一个独立的混凝土建筑元素。这种“智能动态铸造”还表明,需要积累来自许多领域的知识才能创造出这样的成果。

In another corner, a twisted grey column visualized how the programming of „perfect“ concrete could generate a free-standing architectural element in high speed (2cm per minute). This „Smart Dynamic Casting“ also showed that knowledge from many areas needed to be accumulated to create such a result.

© Photo credit: Raphael Kunz

© Photo credit: Raphael Kunz

在一楼,Hannes指着一个木拱结构,并解释了这种几乎绝种的带木钉的木材建筑技术如何通过数字化重新焕发生机。使用这种“空间木材组装”技术,可以在罗马的Instituto Svizzero建造一个凉棚,不需要任何胶水,钉子或螺丝。

On the ground floor Hannes pointed at a wooden arch and explained how a nearly extinct technique of timber-timber construction with dowels could come back to life through digitalization. Using this „Spatial Timber Assemblies“ technique it was possible to build a pergola at the Instituto Svizzero in Rome without any glue, nails or screws.

Arch_Tech_Lab还设有机器人制造实验室。这是一个巨大的机械大厅,配有四个六轴机器人,可在43x16x8m的空间中工作 – 这是全球最大的此类设备。工业机器人手臂的工作公差仅为0.02毫米,悬挂在天花板上。机器人是通用的工业机器臂。研究人员开发工具(所谓的“末端执行器”),为他们提供特殊能力。

The Arch_Tech_Lab also houses the Robotic Fabrication Laboratory. It is a huge machine hall with four six-axis robots that work in a space of 43x16x8 meters – the largest setup of this kind worldwide. The industrial robot arms work with a tolerance of only 0.02mm and are suspended from the ceiling. The robots are generally simple industrial arms. The researchers develop tools (so-called „end effectors“) to give special abilities to them.

© Photo credit: Raphael Kunz

© Photo credit: Raphael Kunz

通过一部电影,Hannes向参观者展示了这样一个配备专用末端执行器的机器人手臂如何仅仅利用砾石和长绳来建造亭子。当然,这是经过各种分析和物理模型的经验测试后的结果。另一个机器人能够生产混凝土加固网 – “网状模具”。机器人创建的自由形式允许在不使用模板的情况下塑造复杂形式的混凝土。

With a movie Hannes showed the visitors how such a robot arm, equipped with a dedicated end effector, could produce a pavilion out of nothing but gravel and a long string. Of course this was the result after various analyses and empirically tests with physical models. Another robot was able to produce reinforcement meshes for concrete – „Mesh Mould“. The free-forms the robot could create allowed complex forms to shape concrete without using formworks.

通过数字制造实验室的参观,Hannes不仅展示了智能机器的新可能性,还解释了从概念到制造的工作流程中人所发挥的控制性作用。建筑数字创新的建成案例都可以在Dübendorf的DFAB House进行参观。

With the tour through the Digital Fabrication Labs, Hannes did not only show the new possibilities coming with the smart machines but also how the digital workflow goes from concept to fabrication, always with humans as the controlling part. Examples of all the digital innovations used in architecture can be visited at the DFAB House in Dübendorf.

© Photo credit: Raphael Kunz

© Photo credit: Raphael Kunz